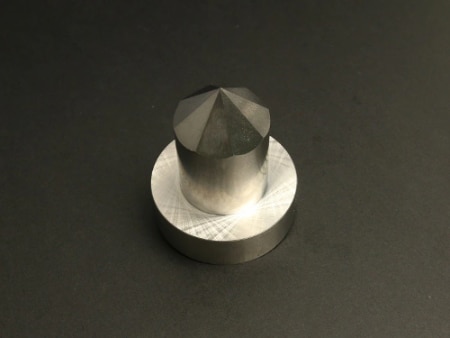

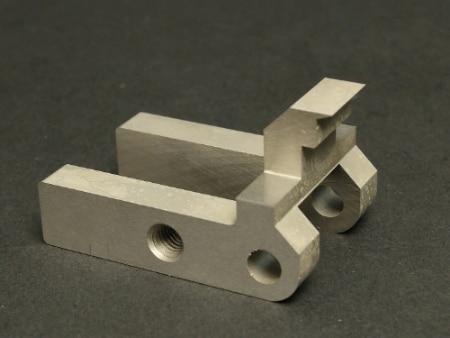

Metal Processing

Surface grinding

Surface grinding is a method of machining the flat surface of an object by using a grinding wheel. It is mainly used when parallelism and flatness are required.

It is generally used for square objects, and while processing, the object is fixed to the magnetic chuck on the surface grinder. By controlling the upper surface of the magnetic chuck, parallelism and flatness can be machined with an accuracy of several microns.

It is also possible to process grooves and steps with an accuracy of a few microns.

In addition, steel, aluminum, stainless steel, cemented carbide, ceramic, and glass can also be machined by changing the grinding wheel.

It is generally used for square objects, and while processing, the object is fixed to the magnetic chuck on the surface grinder. By controlling the upper surface of the magnetic chuck, parallelism and flatness can be machined with an accuracy of several microns.

It is also possible to process grooves and steps with an accuracy of a few microns.

In addition, steel, aluminum, stainless steel, cemented carbide, ceramic, and glass can also be machined by changing the grinding wheel.

Select by Processing Method

Select by Material

Select by Product Application

Micron precision mechanical parts in Vietnam

We process, manufacture and sell molds and jigs. Please feel free to contact us.

Click here for telephone inquiries

Mon-Fri (Excluding Holidays) 9:00-17:00

Feel free to ask any questions

Please contact us.

Please contact us.

Quote

Click here if you wish.

Click here if you wish.

© FINECS Vietnam CO., LTD. All Rights Reserved.